“`html

How Technological Transformations Will Shape Manufacturing Automation by 2025

Advancing Automation Through AI and Machine Learning

As we propel towards 2025, Artificial Intelligence (AI) and Machine Learning (ML) are set to dramatically reshape manufacturing automation. These technologies are not just about enhancing efficiencies; they are revolutionizing the way factories operate. By implementing AI and ML, manufacturers can expect smarter operation models where machines are not only workers but predictive analyzers that prevent downtime and optimize production lines.

For businesses, the adoption of AI translates into more informed decision-making and streamlined operations. It’s a competitive edge that can significantly magnify scalability and adaptability in a dynamic market. Utilizing these technologies for predictive maintenance will also become a cornerstone for those aiming to maintain and increase their market share.

IBM’s reports on AI in manufacturing emphasize how these technologies drive significant reductions in operational costs through enhanced efficiencies. They suggest professional consultation for optimal integration into existing systems to ensure both immediate gains and sustainable growth.

Revolutionized Networking with IoT

The Internet of Things (IoT) is rapidly becoming indispensable in manufacturing, facilitating a more connected and transparent production environment. By 2025, IoT is anticipated to become the backbone of automation, with its ability to link machines, sensors, and systems, enhancing real-time oversight and control over complex manufacturing processes.

This interconnectedness promises significant enhancements in operational efficiency by minimizing waste through the streamlining of production steps. Moreover, real-time data acquisition from IoT devices is critical for manufacturers to remain agile and responsive to market changes and demands.

Experts at Forbes Technology Council recommend adopting IoT solutions that integrate seamlessly with AI enhancements to maximize data utility and support decision-making processes. Integrating comprehensive IoT frameworks can transform traditional plants into smart factories of the future.

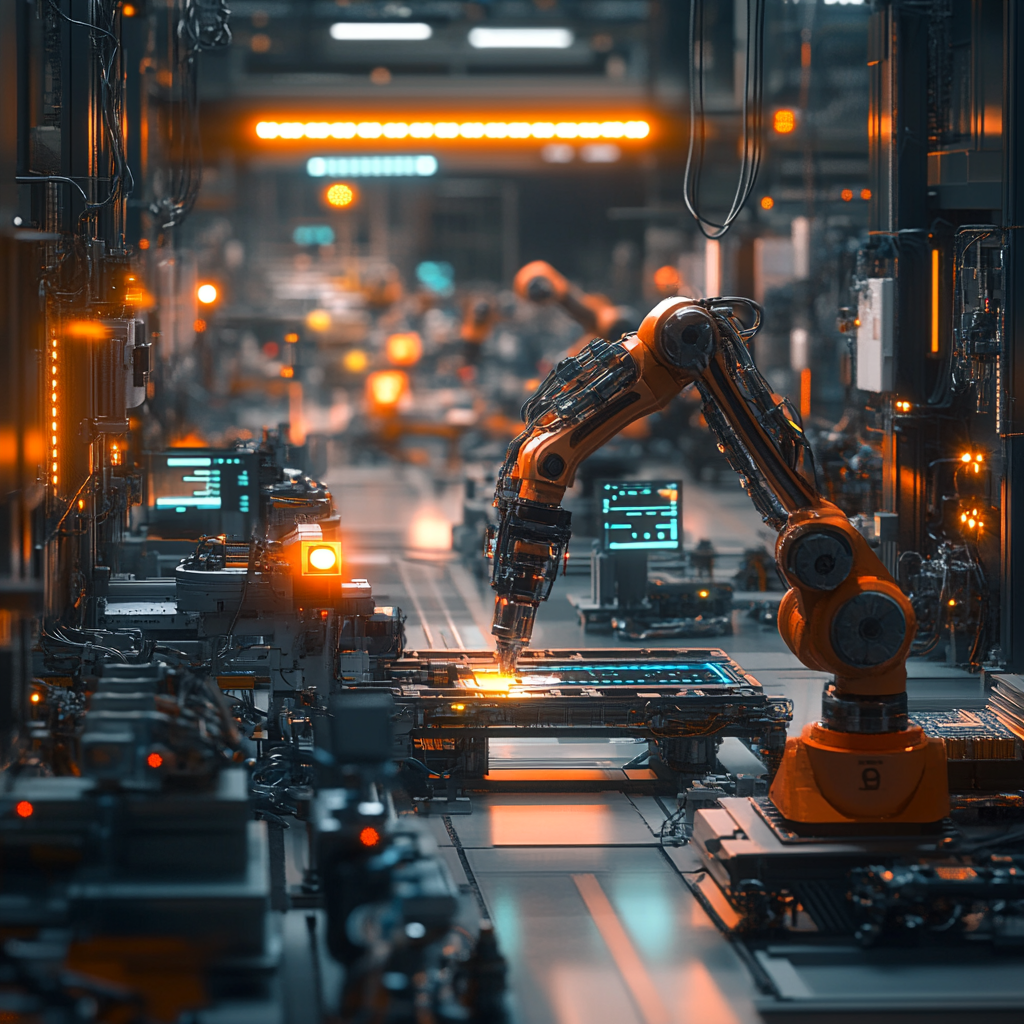

Enhancing Precision with Robotics

Robotics in manufacturing continues to advance, taking over more intricate and hazardous tasks. The improvement in robotics technology by 2025 is expected to provide unprecedented precision and flexibility in manufacturing processes. This shift not only enhances product quality but also drastically cuts down labor costs and workplace accidents.

The inevitable shift towards robots demands a corresponding change in the workforce. There will be a higher demand for workers skilled in STEM, particularly those who can operate, maintain, and improve these automated systems. Companies are urged to invest in continuous learning and upskilling opportunities for their employees to handle more technically advanced tasks.

Industry leaders, such as The Association for Advancing Automation, offer valuable insights into how businesses can integrate robotics seamlessly within their existing frameworks. They provide consultancy services that prove crucial for businesses aiming to enhance their operational efficiency with robotic solutions.

Game-Changing Flexibility with Additive Manufacturing

3D printing, or additive manufacturing, is set to radically alter production dynamics by enabling direct-from-digital manufacturing of complex parts. This technology not only reduces the time and cost involved in production but also enhances flexibility in manufacturing processes, making it perfect for short runs and custom designs.

In industries such as aerospace, where precision and customization are crucial, 3D printing offers a competitive advantage by allowing the creation of lightweight yet durable components. This capacity for personalization will further empower manufacturers to meet specific customer demands without substantial cost hikes.

Studies from MIT’s research labs recommend that manufacturers adopt a phased approach when integrating additive manufacturing, to better manage the transition from traditional methods and to optimize the integration process for maximum efficiency and minimal disruption.

Conclusion

As we look ahead to 2025, it’s clear that the manufacturing sector will undergo significant transformations driven by advanced technologies. The integration of AI, IoT, robotics, and additive manufacturing will not only redefine how products are made but also how plants operate. Manufacturers that embrace these changes and invest in the right technologies will find themselves at the forefront of their industries, perfectly poised to capitalize on new opportunities. Ensuring these integrations are executed under expert guidance will be key to unlocking their full potential.

“`